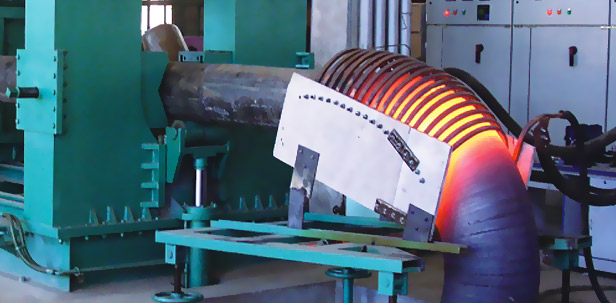

Insulated joint

Insulating joints are an improved replacement product based on the problems of insulating flanges in use. They are an indispensable and important pressure component in the cathodic protection system of steel pipelines. They are widely used in the cathodic protection system of steel pipelines.

Technical Parameters

Service life: same as pipeline; Applicable medium: suitable for oil, gas, water, chemical raw materials, and ore slurry.

Quality requirements

Insulation strength: 2500V 50Hz 1 minute without breakdown or arcing; Insulation resistance: DC 1000V resistance ≥6MΩ; Water pressure test pressure: 1.5 times the design pressure; Air tightness test pressure: equivalent to the design pressure; Non-destructive testing: in accordance with JB4730 -94 100% radiographic flaw detection for all butt joints, 100% magnetic particle flaw detection for other pressure-bearing welds; Groove: API5L standard.

Classification

Rail insulation joint

A high-strength rail insulation joint, in which rail end insulation is placed at the ends of two rails, and groove-shaped insulation plates are clamped on both sides of the joint, and two reinforced fishplates are installed in the grooves of the insulation plate. Then use high-strength bolts to penetrate the reserved holes of the joint and tighten it. The first type of insulation board is a mesh glass cloth slot type insulation board. Its first, third, fifth and seventh layers are paste insulating glue, the second and sixth layers are mesh glass cloth, and the fourth layer is thickened glass. Cloth; The second type of insulating plate is an electric heating sheet groove-type insulating plate, and its first, third, fifth, and seventh layers are insulating film, the second and sixth layers are glass cloth, and the fourth layer is an electric heating sheet with holes.

Structure and principle

The integral insulating joint is composed of the following parts: upper and lower pipes, sleeves, insulating parts, sealing parts, and insulating coating. Between the butting end faces of the upper and lower pipes of the insulating joint, an insulating piece and a sealing piece are clamped to form a double sealing structure with insulating properties. The sleeve adopts two forms of groove welding or direct welding with the upper pipe. The insulator and the upper and lower pipes are firmly enclosed to form a "sealed container", which not only guarantees a good insulation effect, but also greatly improves the insulation The pressure bearing capacity of the structure.

Installation requirements

1. Within 50 meters of the insulation joint installation place, avoid dead holes to be welded;

2.After the insulated joint is connected to the pipeline, it is not allowed to lift the pipeline within 5 meters of the joint; 3. Pressure test of the insulated joint and pipeline instrument.

- TEL- +86-15226756063

- EMAIL- czlsg@163.com

- ADD- Yanta Road Industrial Area, Yanshan,Hebei.