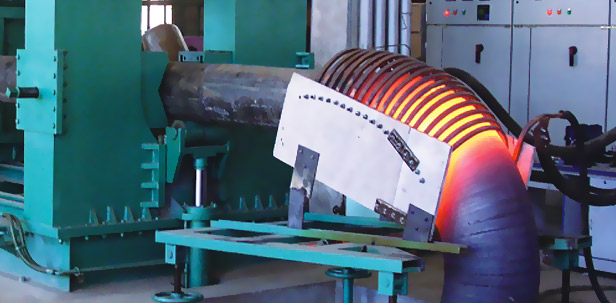

The elastic element that constitutes the main body of its work is non-metallic material, usually a fiber fabric, so it is also called a fabric compensator (expansion joint, expansion joint). There is also rubber material. This material can replace fiber fabric in various working conditions except when it cannot meet the conditions of use under ultra-high temperature (above 400).

Features

⑴ Multi-dimensional direction can be compensated. Various forms, large compensation amount and long life;

⑵ It can effectively compensate or eliminate installation errors;

⑶ Low stiffness and small elastic reaction force;

⑷ High applicable temperature range and good corrosion resistance;

⑸ Can effectively isolate vibration and reduce noise;

In addition to the above features, it also has good sealing, high pressure resistance, high strength, and can withstand mist and a small amount of liquid gas. The use of special rubber can achieve oil resistance, acid and alkali resistance, and aging resistance..

USE:

It is widely used in the entrances and exits of flue gas desulfurization, dust removal equipment, air heating, flow aid blast and other equipment such as steel plants, smelters, petrochemical plants, thermal power plants, cement plants and atomic power plants. It is much better than metal expansion Therefore, it has won unanimous criticism from users and has been vigorously promoted and applied.

Compensator features

The main features of the fiber compensator are as follows:

1. Compensation for thermal expansion: it can compensate for multiple directions, which is much better than a metal compensator that can only compensate for a single type.

2. Compensation for installation errors, because system errors are inevitable during the pipeline connection process, the fiber compensator can eliminate installation errors better.

3. Anti-vibration and vibration isolation: fiber fabric and thermal insulation cotton have the functions of sound absorption and vibration isolation and transmission, which can effectively reduce the noise and vibration of boilers, fans and other systems.

4. No reverse thrust: Because the main material is fiber fabric, it is unable to transmit. The use of fiber compensators can simplify the design, avoid the use of large supports, and save a lot of materials and labor.

5. Good high temperature resistance and corrosion resistance; the selected fluoroplastics and organic silicon materials have good high temperature resistance and corrosion resistance.

6. Good sealing performance; there is a relatively complete production assembly system, and the fiber compensator can ensure no leakage.

7. Light weight, simple structure, convenient installation and maintenance.

8. The price is lower than the metal compensator and the quality is better than imported products.he price is 1/2~1/5 of imported products

Features of non-metallic rubber compensator

In addition to the above advantages

1. Good vibration reduction effect

2. Good sealing performance, using large flanging, no gasket sealing, direct installation, saving cost.

3.Long service life.

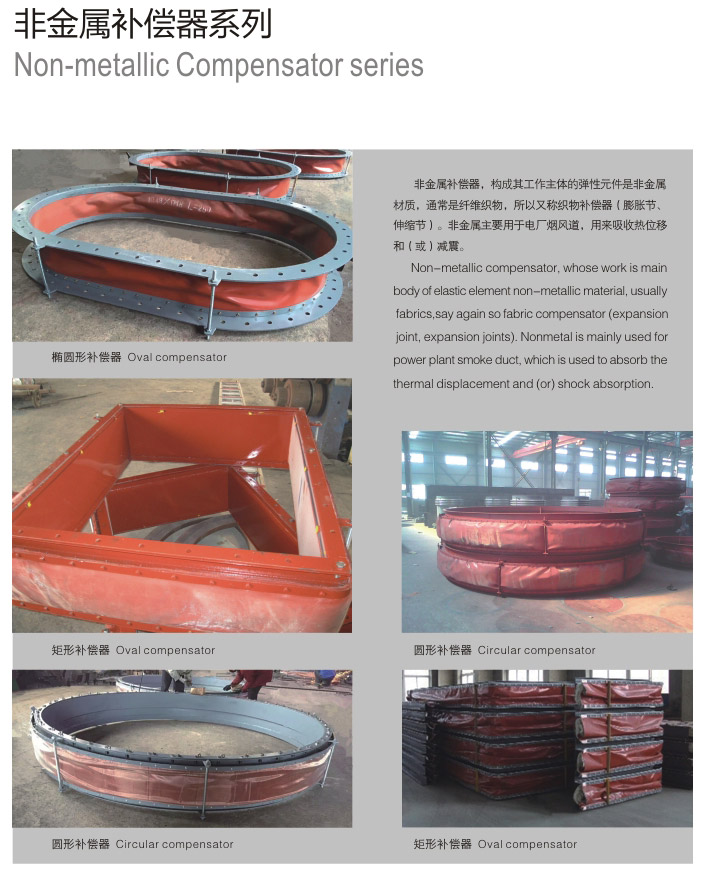

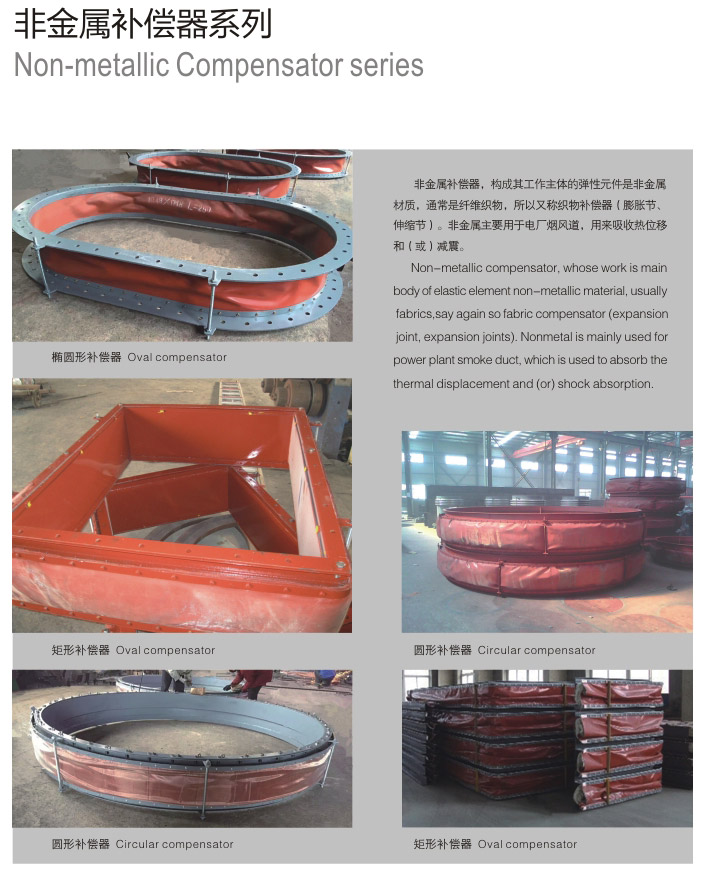

Non-metallic compensator (fabric compensator, fiber fabric compensator)

Uses: The fabric compensator (fiber fabric compensator) can compensate axial and angular directions, has the characteristics of no thrust, simplified bearing design, corrosion resistance, high temperature resistance, noise reduction and shock absorption, etc., especially suitable for hot air ducts and smoke and dust ducts.

Connection mode: ①flange connection type ②takeover connection type

Fabric compensator (fiber fabric compensator) type: ①Duplex ②Angular type ③Square type

Comprehensive performance

The good comprehensive performance of non-metallic compensator makes it widely used in many engineering fields. Pingcheng compensator is usually used for ventilation, dust removal and smoke exhaust and air conditioning insulation pipes and equipment with low working pressure.

In the pipeline system, if there are thermal stresses caused by temperature changes, equipment vibrations and local stresses caused by fixed supports, and stresses caused by system installation deviations, the use of rigid connections will inevitably lead to the weakest point of the pipeline system. Deformation or destruction. If a flexible non-metallic compensator is used, such damage can be avoided. This is related to the unique form of motion of the non-metallic compensator. These motion forms determine the multi-dimensional displacement performance of the non-metallic compensator.

Pressure-bearing single-wave body and multi-wave body compensators have an irreplaceable role under certain special working conditions. An electronic weighing scale used in the desulfurization powder injection system of a steel plant originally used a metal compensator to compensate the equipment and pipelines. Due to the large reverse thrust, the electronic scale was inaccurately debugged, and it was impossible to return to zero and weigh correctly. To change this kind of rectangular caliber, large displacement compensator can only use non-metallic materials to meet the requirements. After special structural design and material design, the working conditions are met.