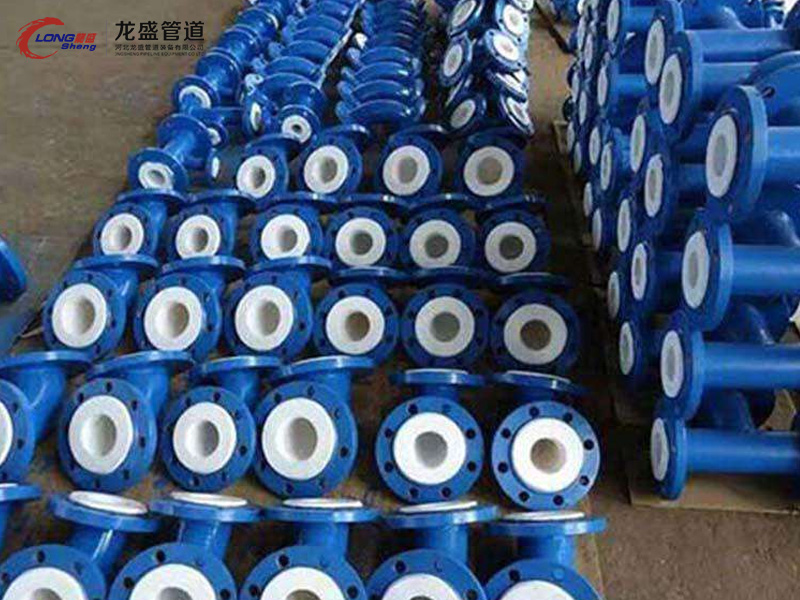

PTFE lined fittings

The friction coefficient of PTFE is extremely small, only 1/5 that of polyethylene, which is an important feature of perfluorocarbon surface. In addition, because the fluorine-carbon chain intermolecular forces are extremely low, PTFE is non-sticky. Polytetrafluoroethylene maintains excellent mechanical properties in a wide temperature range of -196~260℃. One of the characteristics of perfluorocarbon polymers is that they are not brittle at low temperatures. PTFE has a high density, 2.14-2.20g/cm, almost no water absorption, and the equilibrium water absorption rate is less than 0.01%. Polytetrafluoroethylene is a typical soft and weak polymer. The mutual attraction between macromolecules is small, stiffness, hardness, and strength are small, and it will deform under long-term stress.

PTFE is prone to creep when it is loaded, and it is a typical cold-flowing plastic. The creep of PTFE varies with compressive stress, temperature and crystallinity. The higher the temperature, the greater the creep. The crystallinity of PTFE is between 55% and 80%, and the amount of creep does not exceed 2%; when the crystallinity is below 55% and above 80%, the amount of creep increases rapidly. The outstanding feature of PTFE in terms of mechanical properties is its small friction factor, between 0.01-0.10, which is the smallest among existing plastic materials and even all engineering materials.

The friction factor of PTFE increases with the increase of the sliding speed, and tends to be stable when the linear velocity reaches 0.5-1.0m/s or more; and the static friction factor is less than the dynamic friction factor. Using this characteristic in bearing manufacturing can reduce it Starting resistance makes it very stable from starting to running. The friction factor of PTFE decreases as the load increases, and tends to be constant when the load reaches above 0.8MPa. Under high speed and high load, the friction factor of PTFE is lower than 0.01. From ultra-low temperature to the melting point of PTFE, the friction factor is almost unchanged. Only when the surface temperature is higher than the melting point, the friction factor increases sharply. Due to the small intermolecular gravitational force, PTFE has low hardness and is easily worn by other materials. However, as long as the surface roughness of the abrasive material is appropriate, the amount of wear of PTEF can be reduced to a considerable extent.

Polytetrafluoroethylene has extremely high chemical corrosion resistance. For example, when it is boiled in concentrated sulfuric acid, nitric acid, hydrochloric acid, or even in aqua regia, its weight and performance are unchanged, and it is almost insoluble in most solvents, only at 300°C. The above is slightly soluble in all alkanes (about 0.1g/100g). PTFE does not absorb moisture, is non-flammable, and is extremely stable to oxygen and ultraviolet rays, so it has excellent weather resistance. It is worth noting that polytetrafluoroethylene cannot withstand the alkali metal melted in a strong reducing atmosphere, ammonia alkali solution (alkali metal is dissolved in liquid ammonia), some fluorides (such as TFA), naphthalene sodium salt, etc. can corrode quickly Polytetrafluoroethylene products. Polytetrafluoroethylene has low dielectric constant and dielectric loss in a wide frequency range, and has high breakdown voltage, volume resistivity and arc resistance.

The radiation resistance of polytetrafluoroethylene is poor, and it is degraded after being exposed to high-energy radiation, and the electrical and mechanical properties of the polymer are significantly reduced. Polytetrafluoroethylene is produced by radical polymerization of tetrafluoroethylene. Industrial polymerization is carried out under stirring in the presence of a large amount of water to disperse the heat of reaction and facilitate temperature control. The polymerization is generally carried out at 40-80°C and a pressure of 3-26 kgf/cm. Inorganic persulfate and organic peroxide can be used as initiators, or a redox initiation system can be used. 171.38kJ of heat is released during polymerization of tetrafluoroethylene per mole. Dispersion polymerization must add perfluorinated surfactants, such as perfluorooctanoic acid or its salts.

Polytetrafluoroethylene can be formed by compression or extrusion processing; it can also be made into water dispersion for coating, impregnation or making fibers. Polytetrafluoroethylene is widely used in industries such as nuclear energy, national defense, aerospace, electronics, electrical, chemical, machinery, instruments, meters, construction, textiles, metal surface treatment, pharmaceuticals, medical treatment, textiles, food, metallurgy and smelting, etc. , Corrosion-resistant materials, insulating materials, anti-stick coatings, etc., making it an irreplaceable product.

PTFE has outstanding excellent comprehensive properties, high temperature resistance, corrosion resistance, non-stick, self-lubricating, excellent dielectric properties, and a very low friction coefficient. Used as engineering plastics, it can be made into polytetrafluoroethylene pipes, rods, strips, plates, films, etc. It is generally used in corrosion-resistant pipelines, containers, pumps, valves, and radar, high-frequency communication equipment, Radio equipment, etc. Adding any filler that can withstand the sintering temperature of PTFE can greatly improve the mechanical properties while maintaining other excellent properties of PTFE. Filled varieties include glass fiber, metal, metal oxide, graphite, molybdenum disulfide, carbon fiber, polyimide, EKONOL... etc. The wear resistance and limit PV value can be increased by 1000 times.

The polytetrafluoroethylene pipe is made of suspension polymerized polytetrafluoroethylene resin through plunger extrusion processing. Among the known plastics, polytetrafluoroethylene has the best chemical resistance and dielectric properties. Polytetrafluoroethylene braided packing is a good dynamic sealing material, which is woven from expanded polytetrachloroethylene tape. It has low friction coefficient, wear resistance, chemical corrosion resistance, good sealing, no hydrolysis, no Excellent performance such as hardening. Used for gasket seals and lubricating materials that work in various media, as well as electrical insulation, capacitor media, wire insulation, electrical instrument insulation, etc. used under various frequencies.

- TEL- +86-15226756063

- EMAIL- czlsg@163.com

- ADD- Yanta Road Industrial Area, Yanshan,Hebei.